A Ways to Work with Natural and Recycled Materials

A Ways to Work with Natural and Recycled Materials

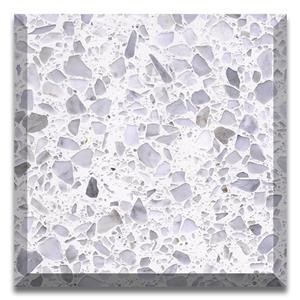

Nowadays, there is a kind of building material called terrazzo, being talked about more and more often. And more and more projects use it as the flooring.

As its name suggests, terrazzo originated in Italy, where marble-workers would take the crumbs of their work home, mix them with cement and create faux-stone floors for their terraces. Since then, terrazzo floors have grown into an art form all their own with a wide range of styles and possibilities. Classic terrazzo is a mixture of marble fragments, called the aggregate, and a cementitious binding agent, called the matrix. It is resilient and can be used inside and outside, and it can be cast in place or laid in manufactured tiles.

More recently, terrazzo manufacturers have used epoxy for the matrix, which is lighter and easier to work with and can be much thinner than traditional cement. Many have also experimented with non-marble aggregates, including recycled materials like glass or metal scraps. After it was introduced in the 20th century, epoxy terrazzo came to dominate the market and became a cost-effective flooring used throughout institutional buildings. There’s a good chance your old high school or office building has epoxy terrazzo somewhere in its halls.

In the 21st century, terrazzo flooring has had a renaissance as architects have looked for new ways to work with natural and recycled materials. The playful graphic effect of large aggregate terrazzo has come into style as designers take inspiration from retro Memphis Group–inspired looks.

Talking about terrazzo, DongXing Group will be certainly mentioned. It is one of the earliest terrazzo manufacturers in China, which has advantages in process and raw materials. Using Italian cement to enhence the product density, brightness and stablility.

----